StarColor Water-based Ink SC9000 Series is a water-based ink for Label , especially for non-porous substrates, including low density polyethylene (LDPE), high density polyethylene (HDPE), polypropylene (PP), polyethylene terephthalate (PET), and biaxially stretched polypropylene film (BOPP), etc. (Some materials need corona treatment).

This series of ink has excellent performance in adhesion, wear resistance and color concentration with higher line number and machine speed.

Product Name: Label Water-based ink

Specification: SC9000-6

Brand: StarColor

Ingredients: Environmental water-borne acrylic resin, advanced organic pigments, water and additives.

Product characteristics: It is non-flammable, explosive, non-toxic, tasteless, harmless to human body, and meets the ROHS international environmental protection requirements.

It has excellent fluidity, good adhesion after printing, anti-wear and scratch, good water resistance, fast drying and high clarity.

Product Usage: Label Printing

Packaging: 5KG/20KG/200KG/barrel

Storage method: Storage temperature is 5 - 35 C, sealed state shelf life is 12 months.

Instructions for Use: Stir well before use to keep the composition of water-based ink in paper cups consistent. Prevent dust falling and knotting

Dry skin, if the remaining ink contains impurities, first filter and then use with the new ink. Measuring Viscosity with Appropriate Ink before Boarding Machine

It is suggested that printing viscosity of 8-12 seconds on the machine can better guarantee the adaptability of water-based ink.

Applicable equipment: flexographic press

Viscosity: 20 + 5S

Fineness: <8 micron

PH value: 8.5-9.0

Drying speed: 40-150 m/min

Colouring power: 90-110

Shelf life: 12 months

Origin: Huizhou City, Guangdong Province

Storage: Keep in a cool and ventilated place, sealed, fire-proof and anti-sluggish, to avoid rain and other pollution.

Notice:

During storage, the barrel cover must be well covered to avoid volatilization of water, resulting in increased viscosity or crust.

Before use, it must be stirred evenly. Please try not to mix with other company's products. The unused products need to be sealed and stored.

注意事項

存儲過程中,桶蓋必須要蓋好,以免水份揮發,造成粘度上升或結皮。

使用前必須攪拌均勻,請盡量不要與其他公司產品混合使用,未用完的出產品需密封存儲。

請在使用前確認方法和效果,如有其他問題,請致電:139 2374 1604

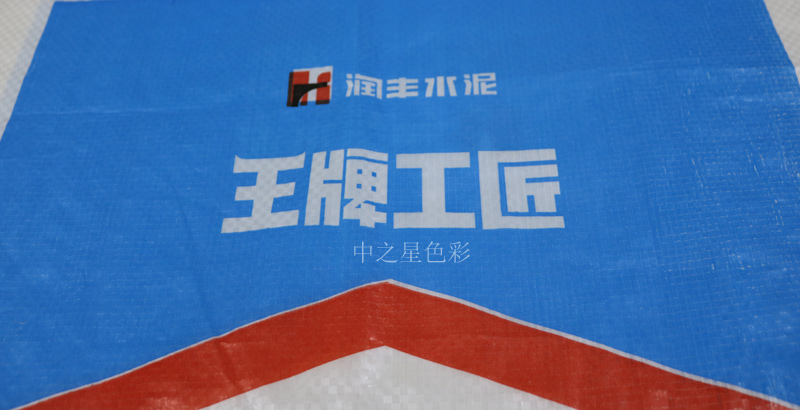

印刷效果圖:

This series of ink has excellent performance in adhesion, wear resistance and color concentration with higher line number and machine speed.

Product Name: Label Water-based ink

Specification: SC9000-6

Brand: StarColor

Ingredients: Environmental water-borne acrylic resin, advanced organic pigments, water and additives.

Product characteristics: It is non-flammable, explosive, non-toxic, tasteless, harmless to human body, and meets the ROHS international environmental protection requirements.

It has excellent fluidity, good adhesion after printing, anti-wear and scratch, good water resistance, fast drying and high clarity.

Product Usage: Label Printing

Packaging: 5KG/20KG/200KG/barrel

Storage method: Storage temperature is 5 - 35 C, sealed state shelf life is 12 months.

Instructions for Use: Stir well before use to keep the composition of water-based ink in paper cups consistent. Prevent dust falling and knotting

Dry skin, if the remaining ink contains impurities, first filter and then use with the new ink. Measuring Viscosity with Appropriate Ink before Boarding Machine

It is suggested that printing viscosity of 8-12 seconds on the machine can better guarantee the adaptability of water-based ink.

Applicable equipment: flexographic press

Viscosity: 20 + 5S

Fineness: <8 micron

PH value: 8.5-9.0

Drying speed: 40-150 m/min

Colouring power: 90-110

Shelf life: 12 months

Origin: Huizhou City, Guangdong Province

Storage: Keep in a cool and ventilated place, sealed, fire-proof and anti-sluggish, to avoid rain and other pollution.

Notice:

During storage, the barrel cover must be well covered to avoid volatilization of water, resulting in increased viscosity or crust.

Before use, it must be stirred evenly. Please try not to mix with other company's products. The unused products need to be sealed and stored.

注意事項

存儲過程中,桶蓋必須要蓋好,以免水份揮發,造成粘度上升或結皮。

使用前必須攪拌均勻,請盡量不要與其他公司產品混合使用,未用完的出產品需密封存儲。

請在使用前確認方法和效果,如有其他問題,請致電:139 2374 1604

印刷效果圖: